Time:2019-12-06 Browse times:788second

Summary

Manufacturing industry is facing increasingly fierce international competition. Enterprises begin to pay more attention to how to respond to market changes quickly and meet customer needs through constantly improving services. However, traditional production site management is like black box operation, which lacks effective monitoring tools for production site information such as real-time output rate, online yield fluctuation, process stability, etc., so the problems can only be remedied after the event, and cannot meet the complex and changeable competition needs. Therefore, how to make the operation transparent, find out the problems that affect the quality and manufacturing cost, improve the timeliness and flexibility of the plan, and improve the operation efficiency of the production line at the same time, has become the concern of enterprises.

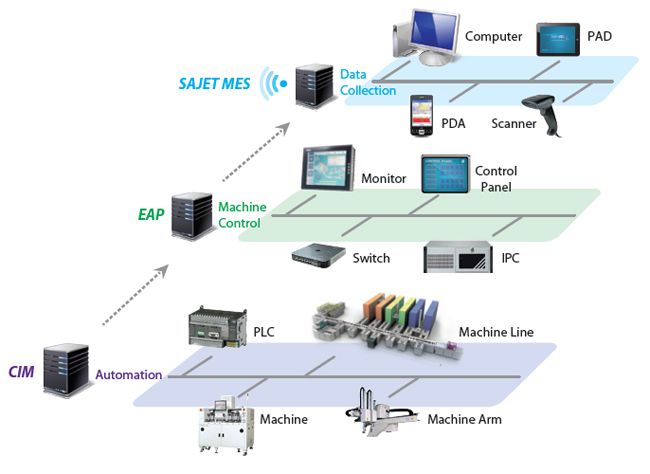

The MES solution integrates the excellent management experience of the top international manufacturing enterprises, integrates the manufacturing elements such as personnel, equipment and materials into the supply chain platform with the concept of lean production, realizes the rapid response of the manufacturing end to the demand from the front-end customers, and helps our partners to forge excellent manufacturing enterprises.

Functional characteristics

MES helps to improve the management of production enterprises

After the implementation of ERP and other management systems, the transparent control and refined management of the production process are put on the agenda. Because MES opens the black box of production, connects the enterprise plan and products, and raises the production and manufacturing process from traditional manual management to information management, Therefore, it has gradually attracted everyone's attention and been paid more and more attention by manufacturing enterprises, and has gradually become an indispensable part of supply chain informatization of manufacturing enterprises.

Solution of manufacturing execution system in electronic assembly industry

Hetek's emes solution aims at the characteristics of the electronic assembly industry and its functional model

Various ways of data acquisition

In order to obtain more production information conveniently and accurately, our MES has designed a variety of different ways to collect manufacturing data in production, including through data acquisition card, device connection, tablet computer, wireless PDA, fixed sensor, DCT, PC or agent agent installed on production test equipment, etc.

Lot data acquisition

Generally, small products take lot as a collection unit and put it in a container. The number of containers for different products may be different. A traveler card is pasted on the container to identify the uniqueness of the container. Lot information collection is mainly to collect container barcode information. The data acquisition operation is divided into four time points, namely, operation station move in, device move in, device move out and operation station move out. Through the operation between these four time points and the device parameter information, multiple efficiency indicators that customers care about can be produced.

Perfect process error proofing

The production process can also guarantee the correctness of the system to reduce the possibility of quality problems. Through our system's perfect process error proofing mechanism, we can ensure that the products follow the correct path, The correct method is adopted by the right person to reduce the possibility of product problems to the greatest extent, improve the quality of products, and reduce the cost of product repair or scrap.

Route visualization

In the process of product production, visual query of production process route is provided, which processes the product should go, which processes it has gone through, and production details are displayed intuitively.

Total material management

Record the material consumption information on the production line in real time, so that users can know the WIP inventory on the production line at any time, and avoid the dead corner of material management

Instant and transparent production process

By querying reports and electronic Kanban, the production management personnel can know the production status in time, find problems in time, adjust the production plan and related resources, and ensure the maximum production efficiency.

Through the electronic Kanban of the production line, the management personnel can know the problems in the production line at a glance, and can know the production progress, personnel allocation, production quality and production efficiency in real time. We can know the production situation of each production line in the whole production workshop, see the production progress of the workshop, and see the top five bad reasons in production, etc

Through this kind of real-time and intuitive information, the management level and efficiency of site management personnel can be greatly improved.

Flexible early warning

Through the early warning function of the system, we can let the relevant personnel discover the problem in time through mail, SMS, alarm light and other ways, eliminate the problem before the problem expands, and reduce the loss caused by it. The system finds abnormalities in the real-time production data collected on site, and then informs the relevant responsible person and stops the line to prevent the problem from expanding and stopping the line. The relevant personnel can continue the production if the measures are correct, otherwise, stop the line for rectification.

Continuous quality improvement

In the emes system of Zhulu, we have designed the SPC trend analysis of IQC incoming inspection, IPQC process sampling inspection, QC open package inspection and production test data. Through a variety of quality reports, quality control personnel can track and manage product quality level, and improve the strength and efficiency of enterprise quality control.

Whole process traceability system

From raw material suppliers, production batch number information, personnel and equipment information in production, production test records, maintenance records, and address and quantity of products after shipment, emes will faithfully record to establish a complete traceability file. When a problem occurs, accurate information can be provided to help the analyst determine the problem and the scope of the impact.