Time:2020-03-03 Browse times:785second

Conform to the development trend of wafer technology, realize ultra-thin and large caliber wafer processing

Gather the essence of existing grinding machine

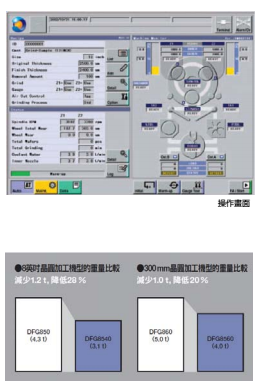

Dfg8540 / 8560 is an upgrade model of dfg800 series with a large number of users all over the world. This model not only has the same technical index and performance as the 800 series, but also has made great improvement in the weight of the equipment. The weight of dfg8540 is reduced

1.2 t (28% lower than dfg850), and the weight of dfg8560 is 1.0 T (20% lower than dfg860).

The ultra-thin wafer under 100 μ M can be precisely milled to improve the functional parameter design of the ultra-thin wafer grinding and handling system, and improve the stability of ultra-thin grinding and finishing.

The system expansion function with the corresponding ultra-thin grinding and finishing technology can be combined with DBG (dividing before grinding = first dividing the wafer, then grinding) and dfp8140 / 8160 to form an online system.

Unify machining points and improve machining reliability

By integrating the position of the grinding point of the first spindle with that of the second spindle, not only the grinding stability of the second spindle is improved, but also the thickness error of the single crystal and the thickness error between the wafers are reduced, and the stability of the ultra-thin grinding quality is improved. The compatibility with the existing dfg800 series and the interchangeability of parts are maintained

Dfg8540 / 8560 maintains interchangeability with existing models, and can use the same grinding wheel, grinding wheel trimming plate and worktable as dfg800 series machines. Easy operation

Dfg8540 / 8560 is equipped with touch LCD timer and graphical user interface (GUI), which improves the operation and profitability. Moreover, the mechanical status and processing status of the equipment can be synchronously displayed on the control screen. As long as the operators touch the graphical button on the control screen, they can simply complete the operation, which not only speeds up the operation speed, but also makes the equipment operation and maintenance very easy.