Time:2019-12-05 Browse times:401second

|

Equipment name: |

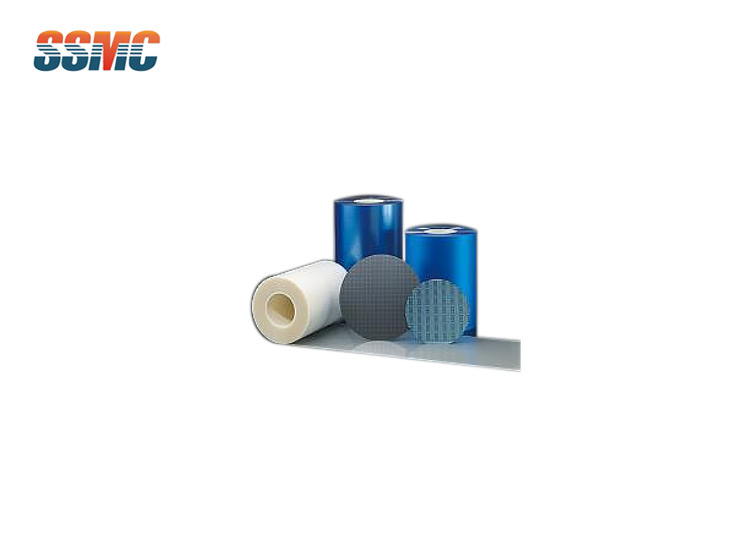

Cutting film |

|

Manufactor: |

DENKA |

|

Model: |

Cutting film |

|

Particular year: |

|

|

Equipment status: |

|

Back Grinding Tape -P Series-

A back grinding tape (hereafter as BG tape) is used for protecting the

circuit surface from scratches, chipping / crack and particle

contamination, during the back-grinding process. The functions of BG

tapes are (1) protecting workpiece surface from contamination, (2)

highly close contact to workpiece and (3) easiness of peeling, and

higher technology to those functions is required with the developments

of jumbo-sized and thinned wafer and high-bumped wafer. Elegrip BG tapes

produced by DENKA do not require to rinse your workpiece after BG

process due to excellent adhesive. We Toyo Adtec consider needs of each

user and choose appropriate tapes.

Feature

Excellent contact to asperity of the circuit side

Effective control of particle

Good water-seepage control

Excellent grinding accuracy (TTV)

Easy peeling

Effective control on adhesive deterioration with time

|

Product Number |

Base Film |

Color |

Total Thickness |

Adhesive Thickness |

|

BGE-122S |

EVA |

LB |

140 |

20 |

|

BGE-122V |

||||

|

BGE-1240A6 |

160 |

40 |

||

|

BGE-124S |

||||

|

BNY-1250A3 |

170 |

50 |

||

|

BNY-1250A4 |

||||

|

BGE-164VC |

200 |

40 |

*The above data is just for representing value, and not guaranteed value.

*Color : MW (Milky White), B (Llight Blue), T (Transparent)

*Separator thickness is not included.

Our company acts as agent for DENKA tape in Japan. The former name of DENKA tape is Toyo tape

DENKA tape includes four films:

1. BG tape, grinding protective film, which is divided into UV type and non UV type.

2. Non UV tape, cutting film, usually blue or white.

3. UV tape, cutting film, can also be used for grinding protection.

4. Peeling tape, used for uncovering after grinding.

Application fields:

1. Grinding protection of semiconductor wafer

2. Cutting process of semiconductor wafer

3. Cutting process of semiconductor back section substrate / copper frame

4. Cutting process of ceramic substrate

5. Cutting process of LED base plate

6. Glass product cutting process

Characteristic:

1. As the agent appointed by DENKA, we have sufficient samples of different types and sizes in our factories in Suzhou and Shenzhen for our customers to choose and test.

2. We have a special UV film application laboratory, which can choose tape according to the actual products of customers, provide cutting test, and finally evaluate whether our products are suitable for the application of customers.

3. Our company is engaged in grinding and cutting OEM business. We have safety stock for common membranes. We can provide emergency delivery support for our customers.